Project Name

Electrical Detection of Cold Corrosion

Responsible:

Senior Researcher: Rasmus Faurskov Cordtz

Professor: Jesper Schramm

Project Partner(s)

MAN Energy Solutions

Project Period

Dec 2018 – ?

Research Funding

A/S D/S Orient’s Fond

Project description

“Cold corrosion” of cylinder liners in large two-stroke marine engines is caused by condensing water and sulfuric acid (from the combustion products) onto the lubed liner surface. Depending on the operating conditions, the condensate can deplete the protective oil film and promote excessive tribo-corrosive liner wear. The problem is especially known when ships operate in humid regions. But, the wear rate cannot be directly measured during operation.

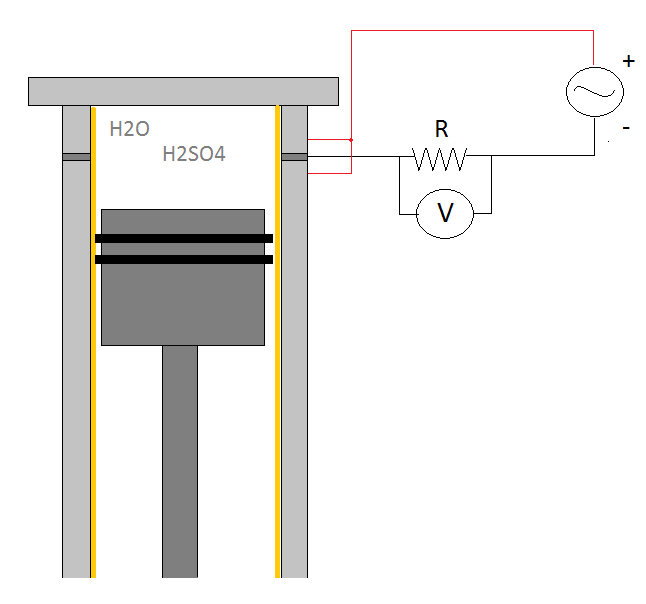

In this project, a sealed electrode is mounted flush with the liner surface of a motored test engine that can simulate “cold corrosion”. When the piston ring passes the electrode, an electric current may flow in the circuit (see figure below). The size of the current is, ideally, a measure of oil film degradation. The oil film alone acts a strong ohmic resistor. Yet, condensed water and acid can permit a current. The aim of this project is to measure liner wear rates (measured as iron accumulation in the oil swamp during simulated “cold corrosion” operation) and compare/correlate the wear with the size of the sensed electrical currents. The technique has potential to be used in large marine engines where it can serve as a tool that alert operators, whereby excessive wear can be prevented through correct lube oil dosing.

Test engine facility (left) and liner with mounted electrode (right) and electrical circuit.