Acronym

Clean Shipping

Project Name

Clean Shipping on Green Fuel

Responsible:

Associate Professor Anders Ivarsson

Project Partner(s)

A.P. Moller-Maersk

Alfa Laval

GreenHydrogen

North China Electric Power University

China-Europe Productivity Center

Shanghai Jiao Tong University

Danfoss Tianjin Co., Ltd.

Chinalco Materials & Application Research Institute Co., Ltd.

Harbin Engineering University

Green Fuel Co. Ltd

Project Period

March 2019 - August 2023

Research Funding

The Danish Ministry of Foreign Affairs, administrated by the Danida Fellowship Center

Project description

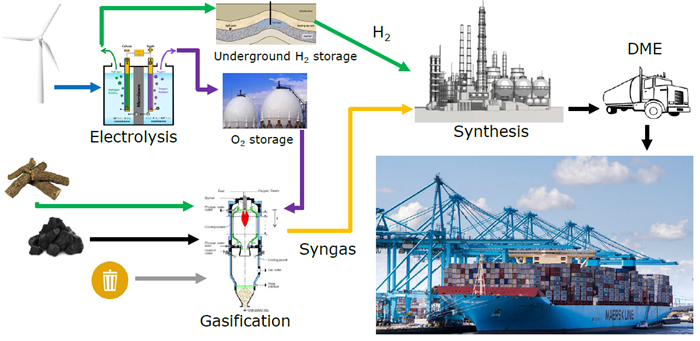

The objective of the project is to develop a machinery concept for large container vessels using Dimethylether (DME) that can be used for the first CO2 neutral deep-sea container ship in 2025. A significant objective of the project is also to develop good collaboration between the most competent and influential forces in Denmark and China in the effort to develop more efficient and greener maritime technologies.

The outcome of the project will be recommendations and cost estimates of:

- ·optimized DME injection in marine engines

- solution of a DME storage and supply system onboard a ship

- DME logistics and production to ensure availability in Chinese ports important for deep sea shipping

- green DME at ports and analysis of price sensitivity

- integrating DME production in the development of RE in China

- ·vessel types and voyage routes suited for the DME concept.

Output will be a final report covering most important aspects of DME as a marine fuel including a business case analysis.

Why DME and why China

DME has unique fuel properties.

- Enables better combustion control than even high quality diesel

- It contains oxygen, which prevents soot formation

- Higher energy density compared to other green fuels

- Handling and storage of DME is similar to LPG, thus conveniently stored as liquid in lightweight gas bottles

- DME is non-toxic and a weak greenhouse gas

- It can be produced efficiently from a large variety of biomasses and sustainable electricity

DME has great potential as a future marine fuel:

- The engine efficiency is determined by the internal combustion pressure, which is limited by the thermal and mechanical stress on components. DME enables better combustion control and a more gentle progression of combustion pressure can be achieved compared to any other fuel. This allow extending the limits for the charge pressure or compression ratio to improve efficiency without increasing the mechanical stress on piston rings

- DME contains no sulfur, thus there is no need for a SOx scrubber to comply with worldwide SOx regulations

- Soot free exhaust gas from DME enables NOx emission limits to be met with high rates of EGR without a fuel consumption penalty and without urea consumption for NOx after treatment

- The fuel saving potential of waste heat recovery may be doubled due to higher achievable rates of EGR and an exhaust gas free of sulfuric acid and soot

China has the world’s largest DME production capacity, which is currently coal based. The project investigates the potential of using existing coal based DME plants in the transition to green production with biomass and renewable electricity as feedstock.